- Metric Thread

- Metric Thread - Bolt Torque table

- Metric Thread - Pitch

- Metric Thread - Tap Drill table

- Metric Thread - Clearance Hole table

- Metric Fine Thread - Bolt Torque table

- Metric Fine Thread - Pitch

- Metric Fine Thread - Tap Drill table

- Metric Wrench Sizes

- Sheet Metal Screws Pilot Hole Sizes

- Cable Gland Sizes

- Trapezoidal Thread Sizes

- Cutting Metric Thread

- Inch Thread

- The Screw

- Drill correctly

- Which Dowel

- Materials

- Language

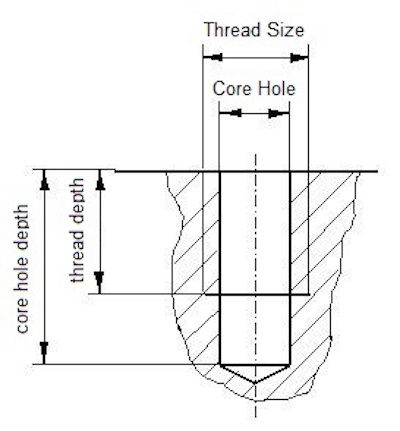

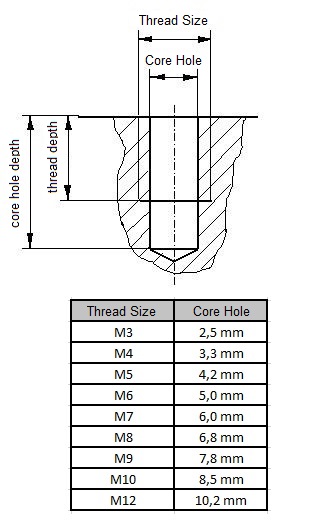

Metric Thread Tap Drill Size

A threaded core hole is a hole into which an internal thread is cut. The core hole must always be

slightly smaller than the nominal diameter of the thread to be cut.

As a rule of thumb for the core hole the following applies:

Thread Nominal diameter - Thread pitch = drill size diameter (Core hole diameter or hole size)

Example: M8 tap drill size

8mm - 1.25 mm = 6.8mm (M8 tap drill size)

A distinction is made between standard threads and fine threads for the drill size diameter. The tap drill size table here shows the core hole size for metric standard threads. The thread tap drill size table for fine threads can be found here.

Metric Thread - Tap Drill Size table

|

Metric thread size |

hole size or drill size (mm) |

pitch regular thread (mm) |

|

M1 drill size |

0,75 | 0,25 |

| M1,1 drill size | 0,85 | 0,25 |

| M1,2 drill size | 0,95 | 0,25 |

| M1,4 drill size | 1,1 | 0,30 |

| M1,6 drill size | 1,3 | 0,35 |

| M1,8 drill size | 1,5 | 0,35 |

| M2 drill size | 1,6 | 0,40 |

| M2,2 drill size | 1,8 | 0,45 |

| M2,5 drill size | 2,1 | 0,45 |

| M3 drill size | 2,5 | 0,50 |

| M3,5 drill size | 2,9 | 0,60 |

| M4 drill size | 3,3 | 0,70 |

| M5 drill size | 4,2 | 0,80 |

| M6 drill size | 5,0 | 1,00 |

| M7 drill size | 6,0 | 1,00 |

| M8 drill size | 6,8 | 1,25 |

| M9 drill size | 7,8 | 1,25 |

| M10 drill size | 8,5 | 1,50 |

| M12 drill size | 10,2 | 1,75 |

| M14 drill size | 12 | 2,00 |

| M16 drill size | 14 | 2,00 |

| M18 drill size | 15,5 | 2,50 |

| M20 drill size | 17,5 | 2,50 |

| M22 drill size | 19,5 | 2,50 |

| M24 drill size | 21 | 3,00 |

| M27 drill size | 24 | 3,00 |

| M30 drill size | 26,5 | 3,50 |

| M36 drill size | 32 | 4,00 |

| M42 drill size | 37,5 | 4,50 |

| M48 drill size | 43 | 5,00 |

| M56 drill size | 50,5 | 5,50 |

| M64 drill size | 58 | 6,00 |

* All information without guarantee.

Core Hole Depth

The thread length should be at least twice and at most three times the nominal thread diameter in order to obtain a tight screw connection. The core hole depth must therefore be slightly more than the desired thread length so that the tap can cut the thread completely. A thread length of more than three times the nominal thread diameter should be avoided, as it does not lead to a better screw connection and has real disadvantages. One should know that 3 to 4 threads bear the full load when screwing! All other threads are so to speak without function.

For example: "M3 core hole". An M3 thread has a nominal diameter of 3mm. This results in a thread length of 6mm to 9mm for (2 x d). As core hole depth you can choose 9mm here.

Table thread length and core hole depth

The required core hole depth depends on the recommended thread length (thread depth). The recommended thread length (thread depth) must be adhered to in order to obtain a secure tight screw connection. The table below shows the thread length (thread depth) from min. to max. A shorter thread means that the screw connection does not meet the required connection force. A longer thread has technically no added value for the screw connection and does not result in a higher connection force.

| Thread depth table | ||

| Thread: | Recommended thread length: | Core hole depth: |

| M3 | 4,5 - 9,0 mm | 9 mm |

| M4 | 6,0 - 12 mm | 12 mm |

| M5 | 7,5 - 15 mm | 15 mm |

| M6 | 9,0 - 18 mm | 18 mm |

| M7 | 10,5 - 21 mm | 21 mm |

| M8 | 12,0 - 24 mm | 24 mm |

| M9 | 13,5 - 27 mm | 27 mm |

| M10 | 15,0 - 30 mm | 30 mm |

| M12 | 18,0 - 36 mm | 36 mm |

* All information without guarantee.